Might be a slim chance  but I trust alot of you crazy people

but I trust alot of you crazy people

I have programed and ran a single tool knee mill for the last 20 years.

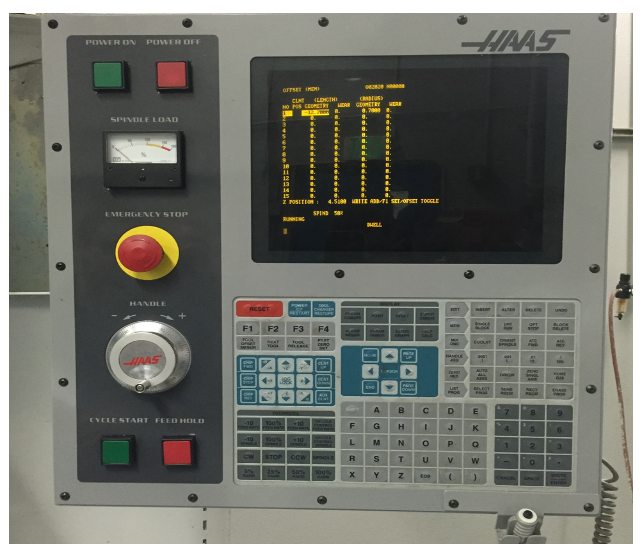

We just purchased a used HAAS mill center about 20-25 years old. So most of the Youtube stuff does not match with the programing.

I have managed to get everything up and running other than getting the correct offsets on the 25 tool vertical tool holder.

I can set up and run "so far any" single tool with the correct z axis offset.

If I add a 2nd to 10th tool and just use the "measure offset" for each tool they do not go to the correct depth.

All tools are set to 9" above the bed then offset to the cutting surface.

I know G54 is for "setting the height" for the offset from the 9" to the bed current parts that number is -2

I am just wondering for each new tool do I have to set a new -2 distance like G55 for T2 G56 for T3 ect ect or does each tool only call in G54 as its a constant number.

Thanks

but I trust alot of you crazy people

but I trust alot of you crazy peopleI have programed and ran a single tool knee mill for the last 20 years.

We just purchased a used HAAS mill center about 20-25 years old. So most of the Youtube stuff does not match with the programing.

I have managed to get everything up and running other than getting the correct offsets on the 25 tool vertical tool holder.

I can set up and run "so far any" single tool with the correct z axis offset.

If I add a 2nd to 10th tool and just use the "measure offset" for each tool they do not go to the correct depth.

All tools are set to 9" above the bed then offset to the cutting surface.

I know G54 is for "setting the height" for the offset from the 9" to the bed current parts that number is -2

I am just wondering for each new tool do I have to set a new -2 distance like G55 for T2 G56 for T3 ect ect or does each tool only call in G54 as its a constant number.

Thanks

.png)