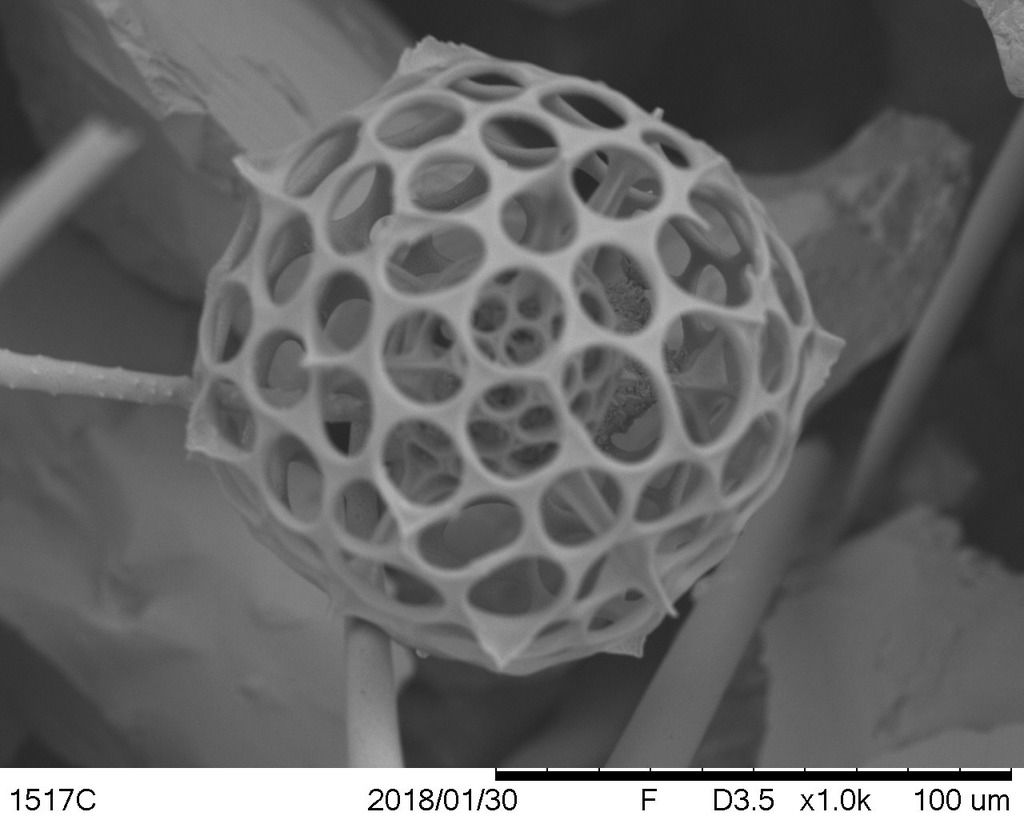

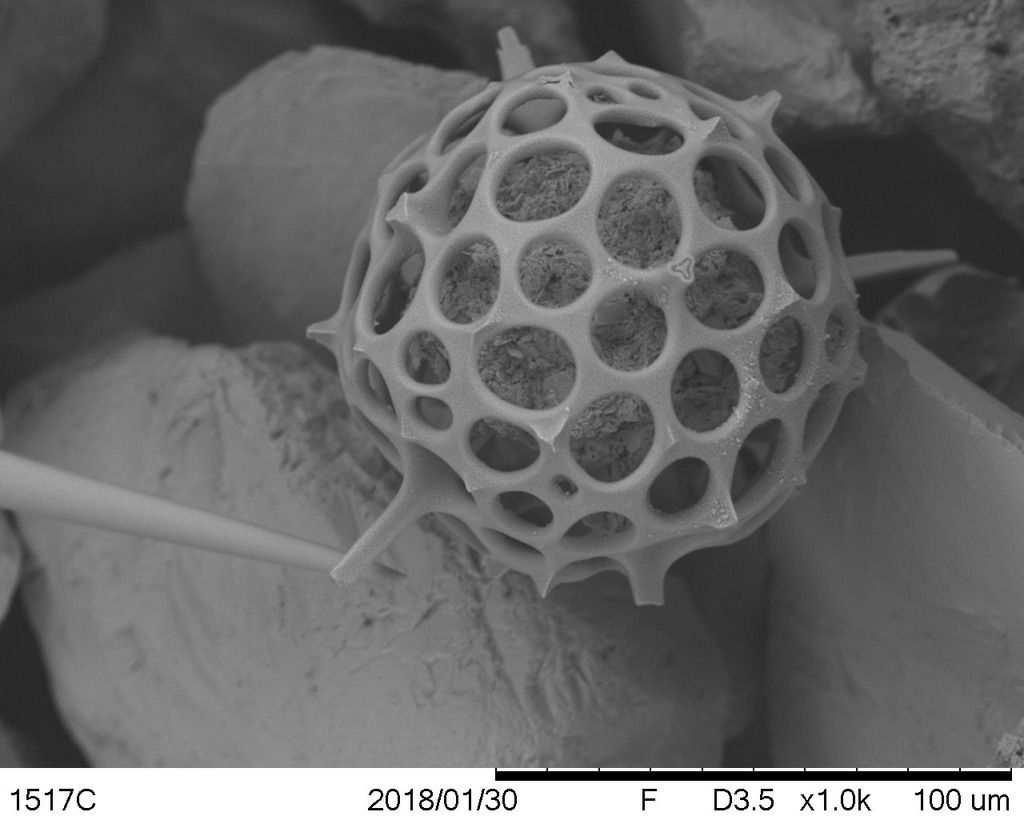

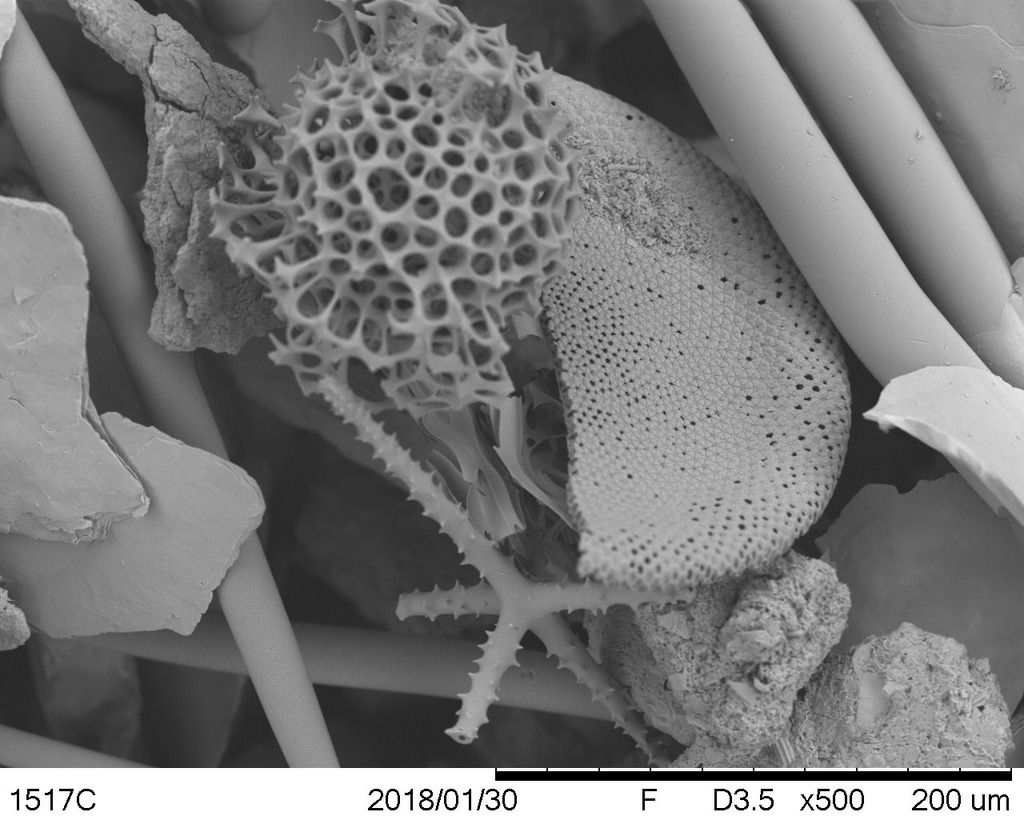

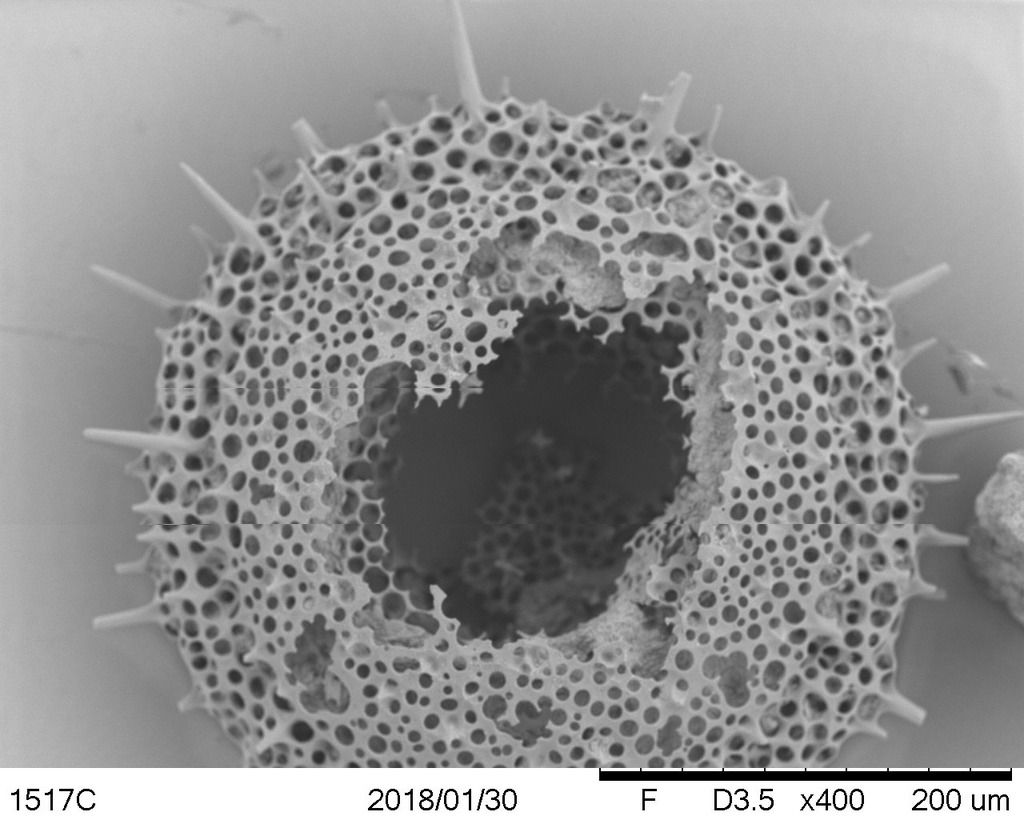

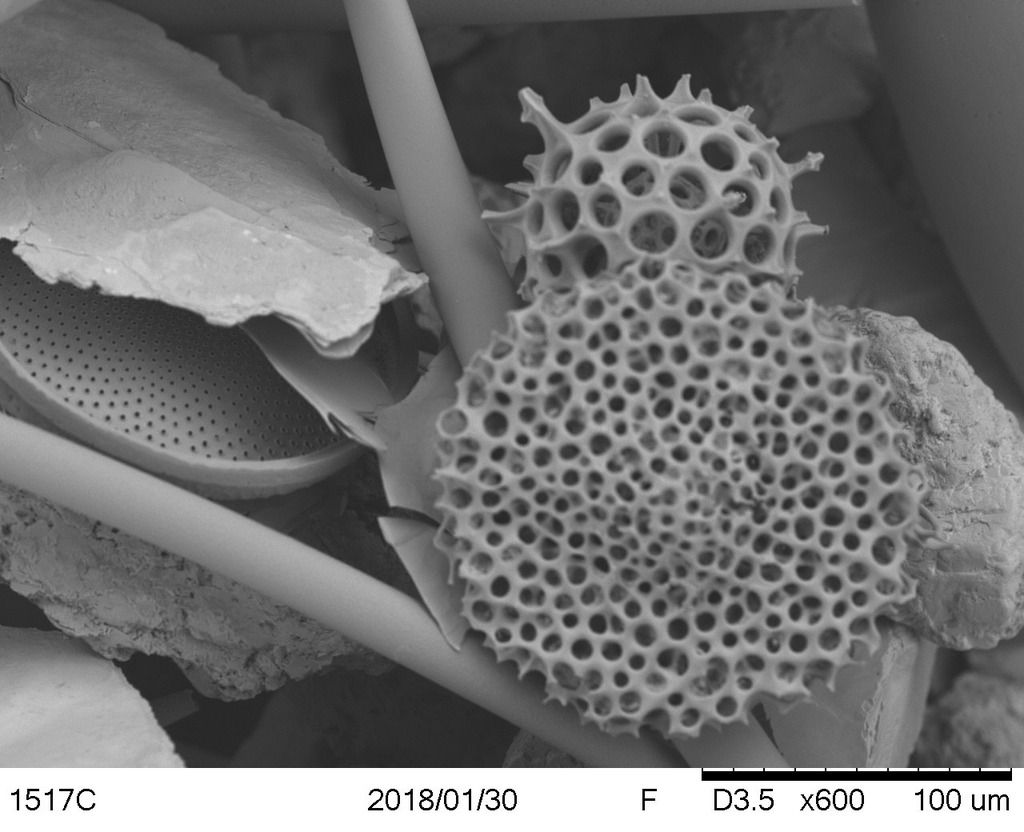

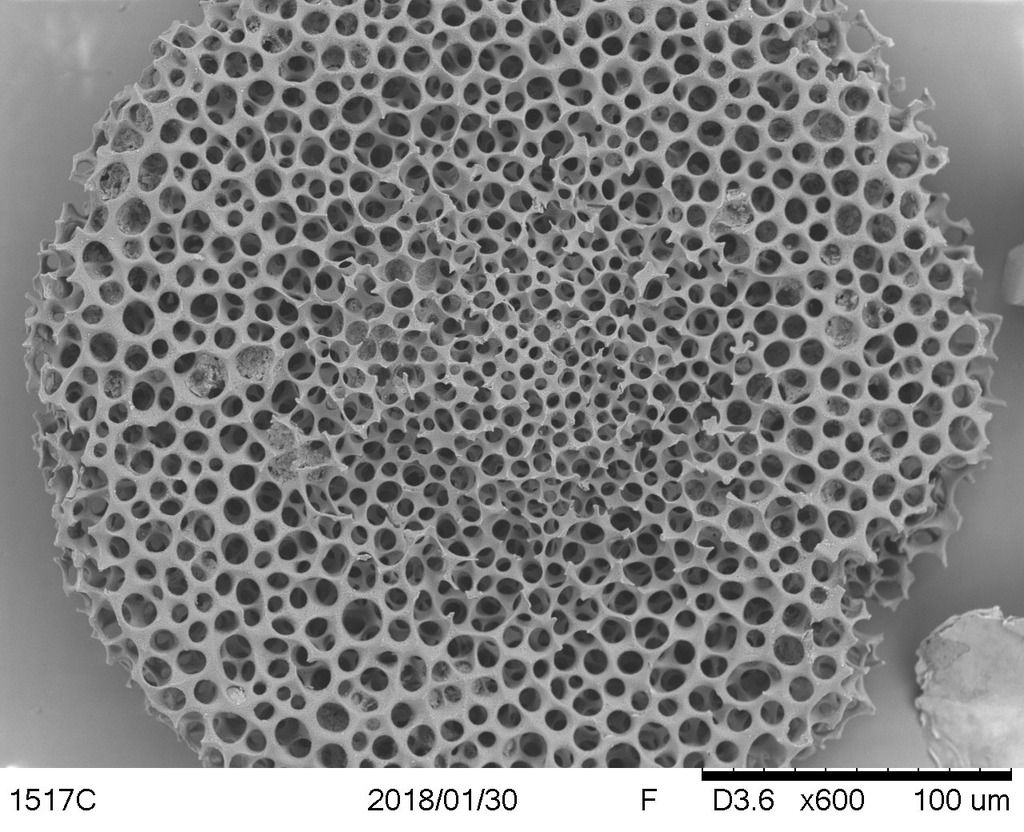

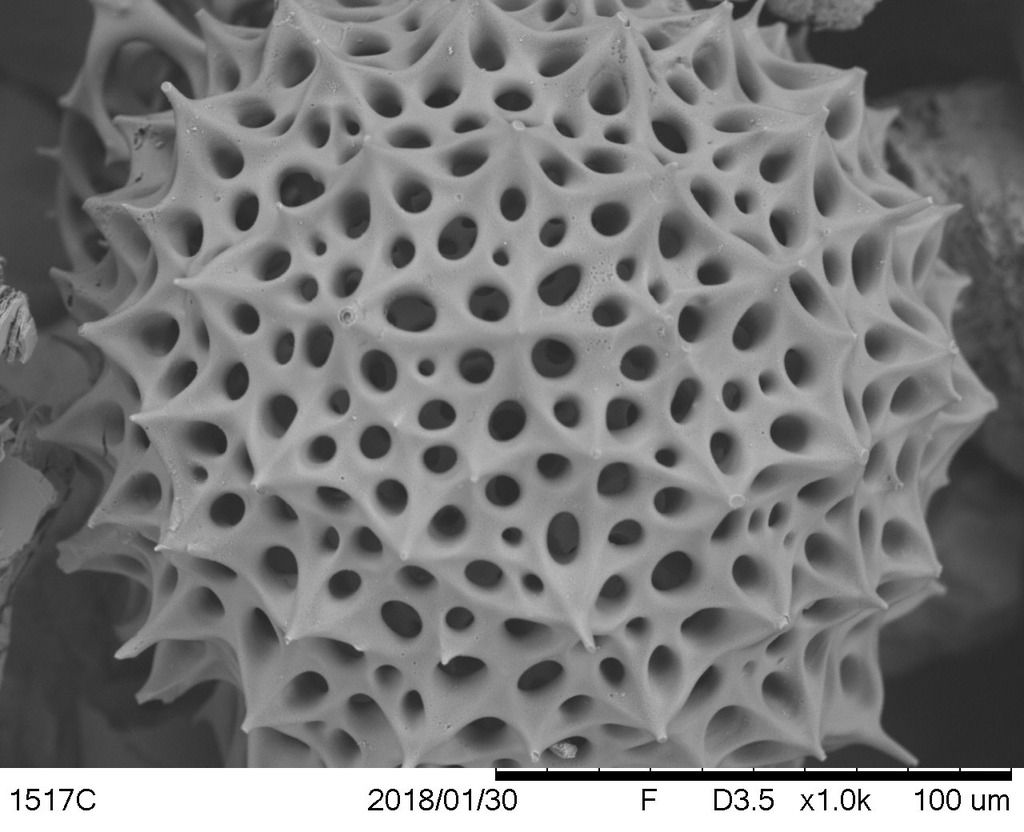

Hi folks. Here some images of radiolaria that were taken with our scanning electron microscope. Enjoy.

https://en.wikipedia.org/wiki/Radiolaria

https://en.wikipedia.org/wiki/Radiolaria