You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

AR Pistol in 7.62x39mm

- Thread starter Maverick44

- Start date

The #1 community for Gun Owners in Texas

Member Benefits:

Fewer Ads! Discuss all aspects of firearm ownership Discuss anti-gun legislation Buy, sell, and trade in the classified section Chat with Local gun shops, ranges, trainers & other businesses Discover free outdoor shooting areas View up to date on firearm-related events Share photos & video with other members ...and so much more!

Member Benefits:

Maverick44

Youngest old man on TGT.

Range Report #1

It went pretty well. I used some old Tula ammo I've had sitting around for just shy of a decade (I wanted an SKS at one point, it didn't happen) to test the gun and get the gas block adjusted. It turns out, I didn't need an adjustable gas block. The port is just about perfect, so the gun wasn't going to be over gassed. It wants that port wide open.

Now, I do have a problem. The adjustment screw is sticking out just a hair too far, and is just barely making contact with the under side of the handguard. I might have it backed out a tad farther than it needs to be to have the port open, so I'll play around with that when I get the time. If not, I can probably either find a slightly shorter screw, or modify this one.

The H3 buffer is doing it's job. From a kneeling position, the cases are making it maybe about 2-3 feet from me and are landing in a nice little pile. Honestly, I could probably get away with swapping out one of the tungsten weights for a steel one, and turn it into an H2. I'll play around with some things and test some more ammo before I do that though.

So, hows the reliability? After the gas block was adjusted, it ran 100% with Tula. Probably around 35 rounds (I only had 40).

The cast bullet rounds did not fare so well. They just don't have the power to cycle the bolt. At least, not the ones loaded with 2400. Even with a standard carbine buffer, they wouldn't cycle the bolt enough to eject. I have a few other loading ready to go, and those are loaded with rifle powders, and are loaded to jacketed levels (but still within the limits of what a coated cast bullet should be able to do). Those might run just fine.

I like this thing, a lot.

It went pretty well. I used some old Tula ammo I've had sitting around for just shy of a decade (I wanted an SKS at one point, it didn't happen) to test the gun and get the gas block adjusted. It turns out, I didn't need an adjustable gas block. The port is just about perfect, so the gun wasn't going to be over gassed. It wants that port wide open.

Now, I do have a problem. The adjustment screw is sticking out just a hair too far, and is just barely making contact with the under side of the handguard. I might have it backed out a tad farther than it needs to be to have the port open, so I'll play around with that when I get the time. If not, I can probably either find a slightly shorter screw, or modify this one.

The H3 buffer is doing it's job. From a kneeling position, the cases are making it maybe about 2-3 feet from me and are landing in a nice little pile. Honestly, I could probably get away with swapping out one of the tungsten weights for a steel one, and turn it into an H2. I'll play around with some things and test some more ammo before I do that though.

So, hows the reliability? After the gas block was adjusted, it ran 100% with Tula. Probably around 35 rounds (I only had 40).

The cast bullet rounds did not fare so well. They just don't have the power to cycle the bolt. At least, not the ones loaded with 2400. Even with a standard carbine buffer, they wouldn't cycle the bolt enough to eject. I have a few other loading ready to go, and those are loaded with rifle powders, and are loaded to jacketed levels (but still within the limits of what a coated cast bullet should be able to do). Those might run just fine.

I like this thing, a lot.

Maverick44

Youngest old man on TGT.

Range Report #2

Not great. It does not like the cast bullets I had made up for it. They had a tendency of not allowing the cartridge to fully seat in the chamber. I'm not sure if they are set out too far or if they're just too fat. Maybe both? I had them set out to 2.200", and knocked a few of them back to 2.180". That didn't seem to help, so I slugged the barrel and cast the chamber using Cerrosafe. The groove is 0.311", and the throat is 0.312". The bullets were sized to 0.3125". Some fed, most didn't. I went ahead and ordered a .311" sizing die. I'll have to break down the rest of what I had loaded. The H4895 I had loaded in some of the rounds was not enough to eject the rounds fully. The BL-C(2) shows some promise. Even at lower charges, the bolt would cycle enough to dump out the fired case and load a new one. The bolt did not lock back though. A stiffer charge and maybe a lighter buffer might get it over the hump.

Not great. It does not like the cast bullets I had made up for it. They had a tendency of not allowing the cartridge to fully seat in the chamber. I'm not sure if they are set out too far or if they're just too fat. Maybe both? I had them set out to 2.200", and knocked a few of them back to 2.180". That didn't seem to help, so I slugged the barrel and cast the chamber using Cerrosafe. The groove is 0.311", and the throat is 0.312". The bullets were sized to 0.3125". Some fed, most didn't. I went ahead and ordered a .311" sizing die. I'll have to break down the rest of what I had loaded. The H4895 I had loaded in some of the rounds was not enough to eject the rounds fully. The BL-C(2) shows some promise. Even at lower charges, the bolt would cycle enough to dump out the fired case and load a new one. The bolt did not lock back though. A stiffer charge and maybe a lighter buffer might get it over the hump.

Maverick44

Youngest old man on TGT.

I got the sizer in, and it helped a little. It's still nowhere near functional with cast yet. After discussing the issue with some cast bullet aficionados, we came to the conclusion that my use of powdercoat is the issue. It's making the nose portion of the bullet too thick. It needs to be around 0.309" to function properly. It's at 0.311". I'm going to try it just lubed like a traditional cast bullet and see how that goes. I also ordered this mold to try with powdercoat. It's a slightly different profile, and it looks like it might work better.

Attachments

Maverick44

Youngest old man on TGT.

UPS dropped off a package today, so I got a little bit of shooting done today.

I readjusted the gas block adjustment screw so that it no longer makes contact with the handguard. It does not appear to have cut off the gas any more. I guess I just had it out a bit too far. I put 60rds of PPU 123gr through the gun, and it was 100% reliable. No hiccups, no nothing. It just ran.

The accuracy is not bad. It's perfectly acceptable for what this gun is, and what I want to do with it. My shitty eyes, and the fact that I was using a magnified red dot are probably keeping me from getting the most out of the gun. I feel that with the right ammo and some more precise optics, I could squeeze about 1 MOA or less out of this gun.

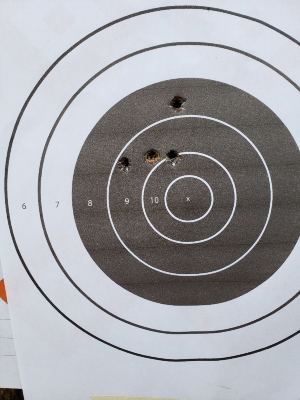

This was shot at the end of my shooting session. 5 rounds in a 1.6" group at 75 yards.

I had a lot of fun popping steel with this. 7.62x39 sure does knock my 8" steel target around. I ran a few rounds of cast through the gun. I'm still having issues with fat bullets, but I was at least able to see that I can get the gun to cycle with cast. The accuracy seems decent. When the new mold gets here, I'll hopefully be able to get this thing running as smooth as it does with jacket ammo.

Sent from my SM-G965U using Tapatalk

I readjusted the gas block adjustment screw so that it no longer makes contact with the handguard. It does not appear to have cut off the gas any more. I guess I just had it out a bit too far. I put 60rds of PPU 123gr through the gun, and it was 100% reliable. No hiccups, no nothing. It just ran.

The accuracy is not bad. It's perfectly acceptable for what this gun is, and what I want to do with it. My shitty eyes, and the fact that I was using a magnified red dot are probably keeping me from getting the most out of the gun. I feel that with the right ammo and some more precise optics, I could squeeze about 1 MOA or less out of this gun.

This was shot at the end of my shooting session. 5 rounds in a 1.6" group at 75 yards.

I had a lot of fun popping steel with this. 7.62x39 sure does knock my 8" steel target around. I ran a few rounds of cast through the gun. I'm still having issues with fat bullets, but I was at least able to see that I can get the gun to cycle with cast. The accuracy seems decent. When the new mold gets here, I'll hopefully be able to get this thing running as smooth as it does with jacket ammo.

Sent from my SM-G965U using Tapatalk

Attachments

Maverick44

Youngest old man on TGT.

Staff online

-

robertc1024Moderator

-

VaqueroMoving stuff to the gas prices thread.....

Members online

- Fishkiller

- 007FJ

- brashears9567

- Trooper Glen

- mroper

- Dred

- TwentyFive

- kbaxter60

- Wabbit69

- Big Green

- no2gates

- Wmb556

- buckshot4900

- Texan79423

- crzy_one

- GMK

- 480 Ruger

- TipBledsoe

- johnbeaver

- Johnny Diamond

- Neat57

- txraised214

- Gordo

- jjkukla

- ShootTheBreeze

- Bob1911

- Austinpilot69

- GunZoneDeals.Com

- DubiousDan

- PoolBoy22

- thescoutranch

- BRD@66

- Txdweeb

- Ausländer

- D0ntTr3@d0nM3

- TicToc26

- WesW

- robertc1024

- Vaquero

- motorcarman

- texcross

- madwildcat

- CodyK

- lastnline75

- jertex

- GaryS

- roadkill

- Lead Belly

- Sasquatch

- Brains

Total: 1,137 (members: 87, guests: 1,050)